How Mike Started

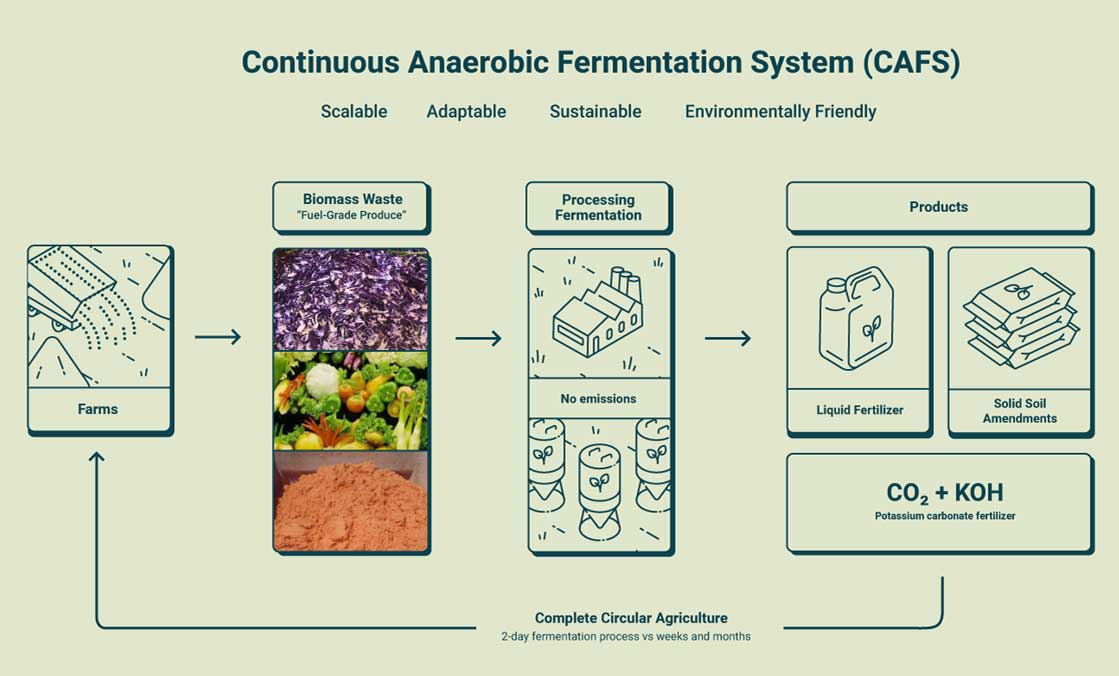

For more than 40 years Anaerobe Systems has been a world leader in Anaerobe Science. After ten years of research and development Mike Cox, founder, and CEO, accomplished what many considered impossible by patenting the Continuous Anaerobic Fermentation System (CAFS).

Mike’s original intent was to use the fermentation process to make hydrogen, a clean fuel. However, one day Mike was showing the system to a close friend and commercial farmer. During the discussions he asked about the waste material, which came from plants, and asked if he could send it out for analysis. He came back and said, “I’m paying a lot of money for what you’re throwing away. You have a fantastic fertilizer.’ So, we started making fertilizer.”

We’re really seeing a change in agricultural practices and knowledge from farmers and gardeners looking for less synthetic chemical combinations. The components in our fertilizer and soil amendment are readily beneficial to the soil, plants, microbes, fungi, and everything in the soil. They have a low NPK, but there are benefits that aren’t in other fertilizers.

We are also seeing a change in regulatory requirements to reduce nitrogen application to crops and reduce climate pollutant emissions. Our process helps solve both problems.

Anaerobe Systems formed a new division, Anaerobe Energy, in 2018 to commercialize CAFS and introduce the technology to the world. FermeGROW™ Liquid Fertilizer, the first available product, was released in 2019 and the following year was approved by the California Department of Food and Agriculture (CDFA) as FermeGROW™ Organic Liquid Fertilizer, followed by FermeCHAR™.